Type 10

Range of pumps for resins and hardeners

The pumps in the Type 10 family are available in four sizes: 1610 / 2610 / 3610 / 4610. Each size differs in terms of the flow range it offers and can be supplied with different product inlet/outlet configurations, depending on requirements and the type of application (see the model overview table below).

The Type 10 pump range is the perfect choice for your dosing machine in many applications, including the following examples:

- Polyurethane

- Joint removal

- Collage

- Chemistry

- Automotive

- Aeronautics

- Etc.

General

► Product dosed

resins, silicones, hardeners, solvents, oil, greases, sealants, etc.

► Applications

Automotive, aerospace, chemicals, renewable energy, electronics, etc.

► Viscosity

from 10 to 1,000,000 mPas

► Speed

from 10 to 200 rpm

► Nominal accuracy

±2% of nominal value

► Repetability

0.1 % of previous value

► Materials

hardened stainless steel, 316L, 316Ti

► Operating set

Reduced, standard, enlarged (depending on viscosity)

Each pump can be adapted to the situation, making it possible to dose products ranging from very low viscosity (e.g., amine or acetone) to very high viscosity (e.g., sealants or silicones) by varying the operating clearances during manufacture.

This type of pump is made entirely of stainless steel, allowing for the precise dosing of a wide range of liquids, such as:

- Resins (epoxy, polyester, polyol, acrylics, etc.)

- Silicones

- Hardeners (isocyanate, peroxide, etc.)

- Solvents

- Water

- Oils

- Fats

- Mastics

- etc.

A coating ADLC All friction surfaces in contact with the product can be coated when dosing abrasive products, and internal modifications can also be made to the pump to enable the dosing of products containing particles.

All pumps in this range have one or more types of drive shaft seals that are very easy to maintain and replace during servicing, without having to dismantle the entire pump.

The different models presented below differ mainly in their input/output configuration.

Models

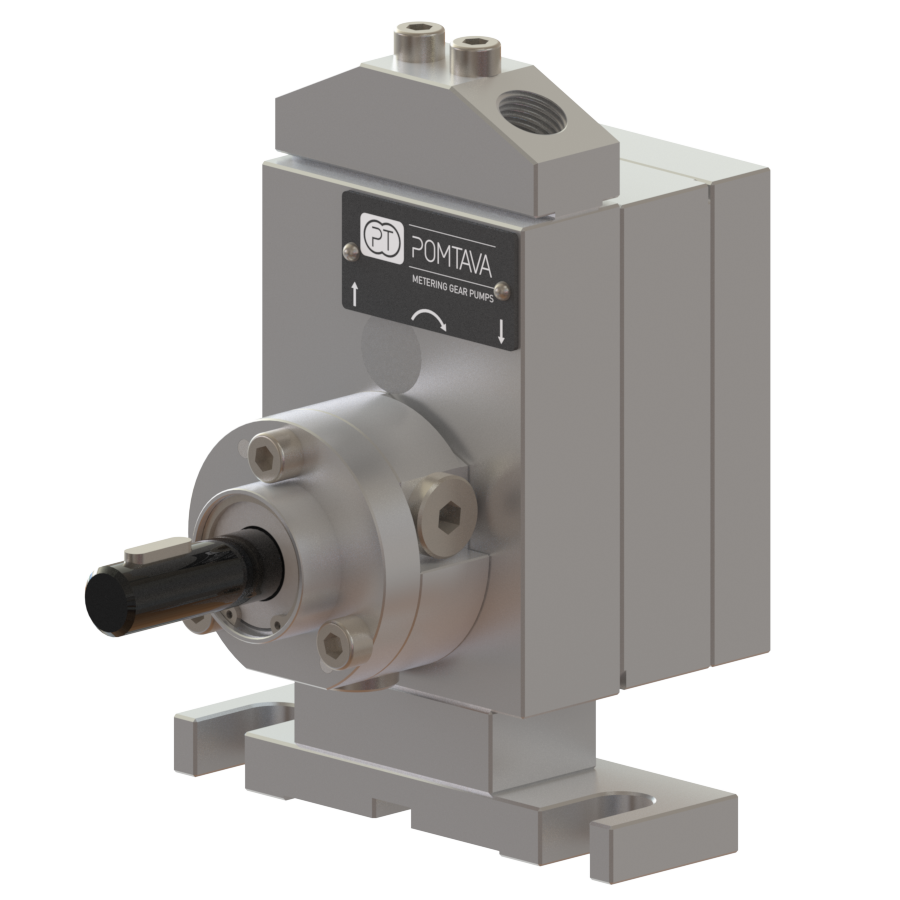

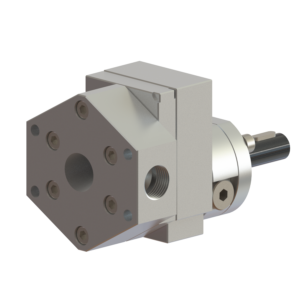

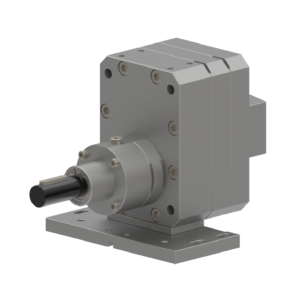

Group 1

1610-1

- Displacement (cc/rev)

0.05 – 0.1 – 0.3 – 0.6 – 1.2 – 1.8 – 2.4 – 3.0

- Flow rate (ml/min)

0.5 to 10 – 1 to 20 – 3 to 60 – 6 to 120 – 12 to 240 – 18 to 360 – 24 to 480 – 30 to 600

- Working pressure

Up to 15 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/8″ / G1/4″ / G3/8″ (connection block for optional pressure transmitters)

- Tree height

40mm (other heights optional)

- Option

Machining for heating cartridge

- Option

Modification for difficult products

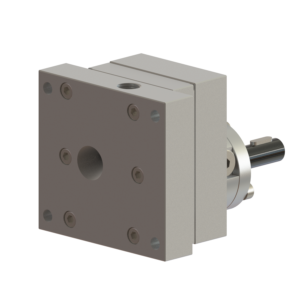

Group 2

2610-1

- Displacement (cc/rev)

1.2 - 2.4 - 3.0 - 6.0 - 10.0

- Flow rate (ml/min)

12 to 240 - 24 to 480 - 30 to 600 - 45 to 900 - 60 to 1200 - 100 to 2000

- Working pressure

Up to 15 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/8″ / G1/4″ / G3/8″ (connection block for optional pressure transmitters)

- Tree height

51mm (other heights optional)

- Option

Machining for heating cartridge

- Option

Modification for difficult products

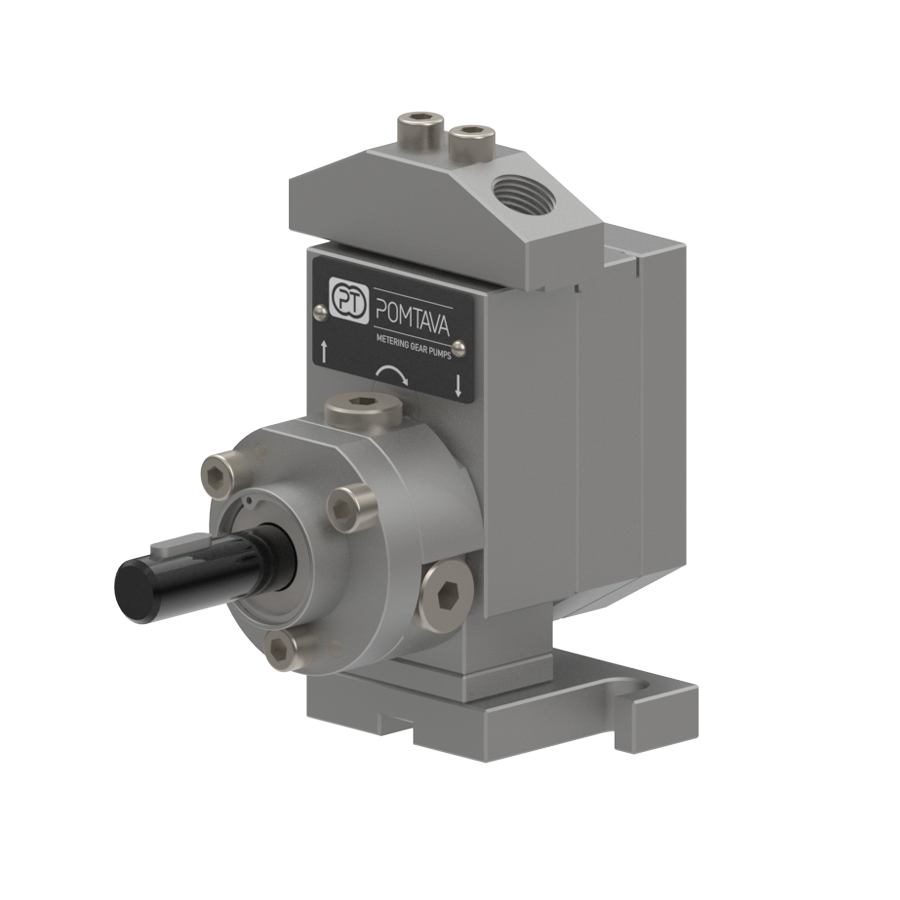

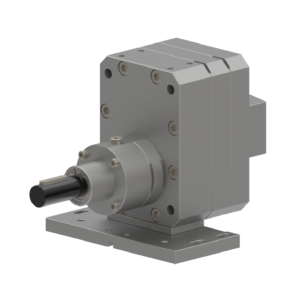

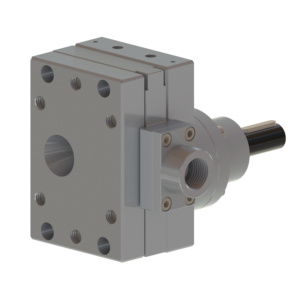

Group 3

3610-1

- Displacement (cc/rev)

6.0 - 10.0 - 16.0 - 22.0

- Flow rate (ml/min)

60 to 1200 – 100 to 2000 – 160 to 3200 – 220 to 4400

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/4″ / G3/8″ / G1/2″ (connection block for optional pressure transmitters)

- Tree height

79mm (other heights optional)

- Option

Machining for heating cartridge

- Option

Modification for difficult products

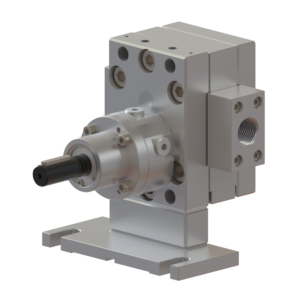

Group 4

4610-1

- Displacement (cc/rev)

35.0 – 50.0 – 70.0 – 100.0

- Flow rate (ml/min)

350 to 7,000 – 500 to 10,000 – 700 to 14,000 – 1,000 to 20,000

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/4″ / G3/8″ / G1/2″ (connection block for optional pressure transmitters)

- Tree height

79mm (other heights optional)

- Option

Machining for heating cartridge

- Option

Modification for difficult products

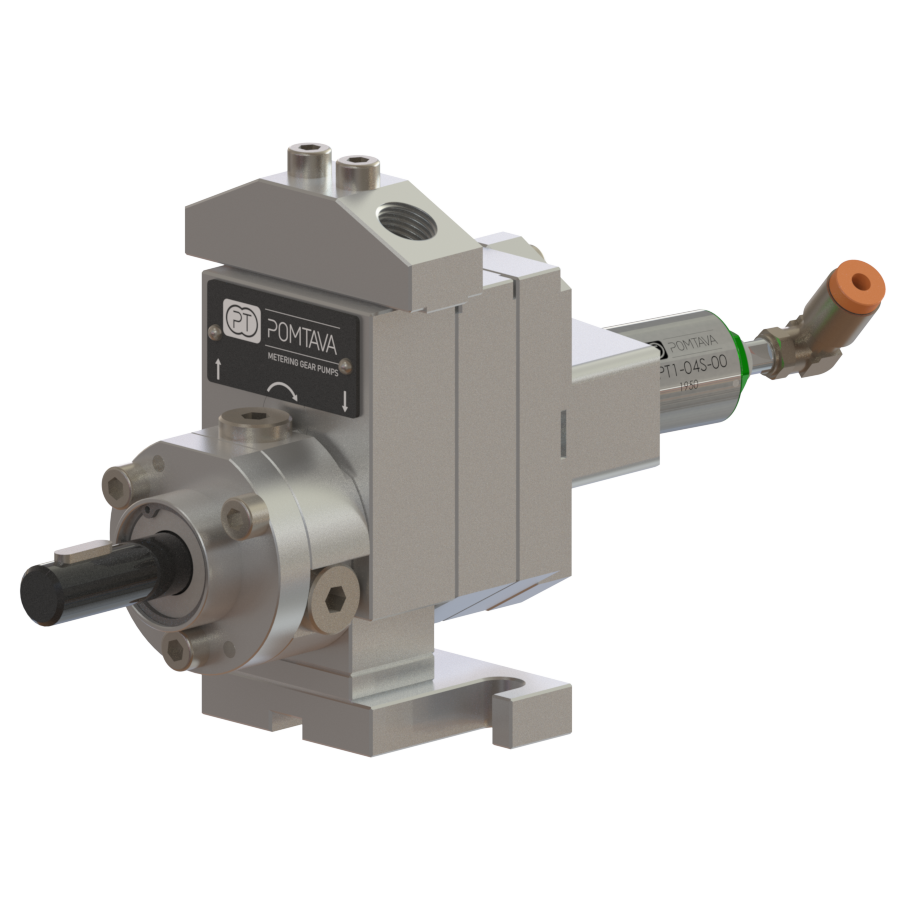

Group 1

1610-2

- Displacement (cc/rev)

0.3 - 0.6 - 1.2 - 1.8 - 2.4 - 3.0

- Flow rate (ml/min)

3 to 60 - 6 to 120 - 12 to 240 - 18 to 360 - 24 to 480 - 30 to 600

- Working pressure

Up to 15 bar

- ADLC processing

(optional)

- I/O location

Rear entry, side exit on the cover

- Connection

G1/4" / G3/8"

- Option

Machining for heating cartridge

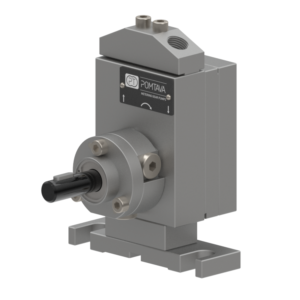

Group 2

2610-2

- Displacement (cc/rev)

1.2 - 2.4 - 3.0 - 6.0 - 10.0

- Flow rate (ml/min)

12 to 240 - 24 to 480 - 30 to 600 - 45 to 900 - 60 to 1200 - 100 to 2000

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

Rear entry, side exit on the cover

- Connection

G1/4"

- Option

Machining for heating cartridge

- Option

Modification for difficult products

Group 3

3610-2

- Displacement (cc/rev)

6.0 - 10.0 - 16.0 - 22.0

- Flow rate (ml/min)

60 to 1200 – 100 to 2000 – 160 to 3200 – 220 to 4400

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

Rear entry, side exit on the cover

- Connection

G1/4″ / G1/2″

- Option

Machining for heating cartridge

- Option

Modification for difficult products

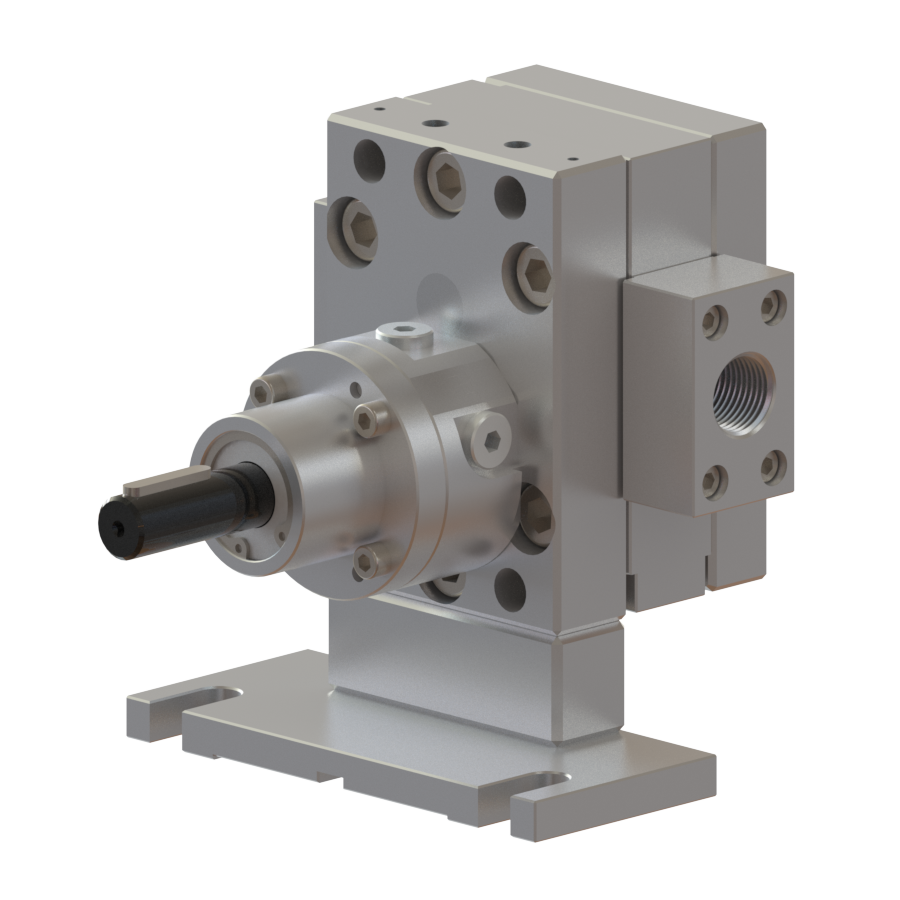

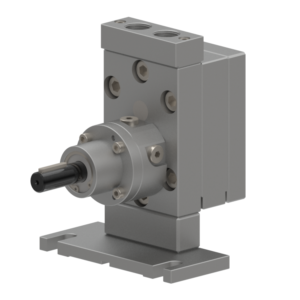

Group 3

3610-3

- Displacement (cc/rev)

6.0 - 10.0 - 16.0 - 22.0

- Flow rate (ml/min)

60 to 1200 – 100 to 2000 – 160 to 3200 – 220 to 4400

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

On the sides of the core

- Connection

G1/4″ (6.0cc) / G1/2″ (10.0cc/16.0cc) / G3/4″ (22.0cc)

- Tree height

79mm (other heights optional)

- Option

Modification for difficult products

Group 4

4610-3

- Displacement (cc/rev)

35.0 – 50.0 – 70.0 – 100.0

- Flow rate (ml/min)

350 to 7,000 – 500 to 10,000 – 700 to 14,000 – 1,000 to 20,000

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

On the sides of the core

- Connection

G1"

- Tree height

79mm (other heights optional)

- Option

Modification for difficult products

Group 1

1610-4

- Displacement (cc/rev)

0.05 – 0.1 – 0.3 – 0.6 – 1.2 – 1.8 – 2.4 – 3.0

- Flow rate (ml/min)

0.5 to 10 – 1 to 20 – 3 to 60 – 6 to 120 – 12 to 240 – 18 to 360 – 24 to 480 – 30 to 600

- Working pressure

Up to 15 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/8″ / G1/4″ / G3/8″ (connection block for optional pressure transmitters)

- Tree height

40mm (other heights optional)

- Types 1610-4-2

Bypass version

- Option

Machining for heating cartridge

- Option

Modification for difficult products

Group 2

2610-4

- Displacement (cc/rev)

1.2 - 2.4 - 3.0 - 6.0 - 10.0

- Flow rate (ml/min)

12 to 240 - 24 to 480 - 30 to 600 - 45 to 900 - 60 to 1200 - 100 to 2000

- Working pressure

Up to 15 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/8″ / G1/4″ / G3/8″ (connection block for optional pressure transmitters)

- Tree height

51mm (other heights optional)

- Types 2610-4-2

Bypass version

- Option

Machining for heating cartridge

- Option

Modification for difficult products

Group 3

3610-4

- Displacement (cc/rev)

6.0 - 10.0 - 16.0 - 22.0

- Flow rate (ml/min)

60 to 1200 – 100 to 2000 – 160 to 3200 – 220 to 4400

- Working pressure

Up to 100 bar

- ADLC processing

(optional)

- I/O location

On the back, on the cover

- Connection

G1/4″ / G3/8″ / G1/2″ (connection block for optional pressure transmitters)

- Tree height

79mm (other heights optional)

- Types 3610-4-2

Bypass version

- Option

Machining for heating cartridge

- Option

Modification for difficult products

Contact

Do you have any questions? Please fill in the form below to contact our sales department.

"*" indicates required fields