PZS injection head

For RTM technology injection

The PZS-100, PZS-200 and PZS-600 injection heads connect the RTM machine to the injection point, becoming an integrated element controlled by the latter. This assembly ensures injection under the best possible conditions: no consumables, no resin leakage, automatic cleaning and easy maintenance.

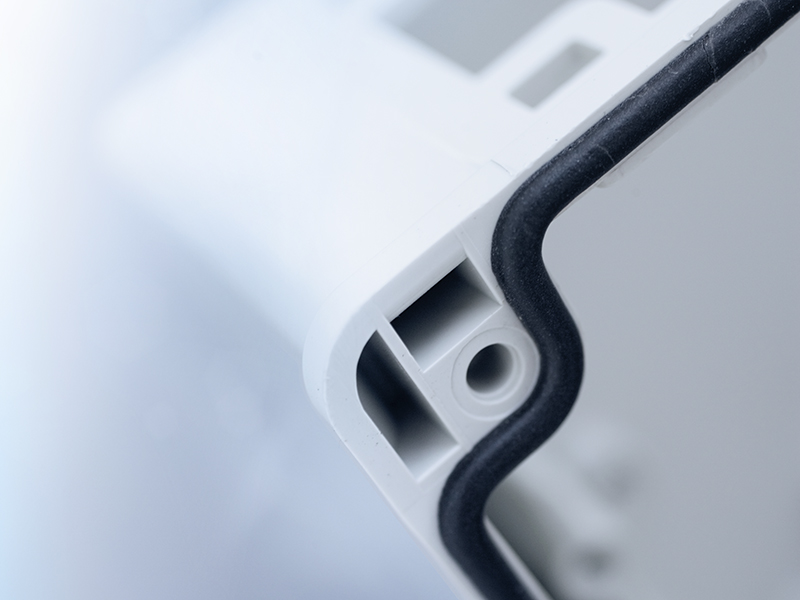

They also ensure a perfect seal between the mold and the injection point, good pressure maintenance and perfect cleaning during the machine cycle.

They are suitable for various types of resin, including epoxy and polyester resins (single- or two-component, filled or unfilled).

PZS injection heads are equipped with an internal temperature control circuit (hot or cold) depending on the resins and molds used, as well as a housing for a pressure transmitter.

Operation is by pneumatic cylinder. In the "injection" (open) position, the needle retracts, allowing resin to pass into the mold. In the "rinsing" (closed) position, the passage to the mold is closed, and a rinsing channel opens to allow cleaning agent to pass through the head.

Depending on the application, different mold seats (with or without lugs) and plugs are available. We can also adapt the heads to your needs: flow rate, pressure, temperature.

The PZS-100, PZS-200 and PZS-600 injection heads work in perfect harmony with the PZS-400M, PZS-450M and PZS-500M mixing head range.

Models

RTM light / RTM eco injection head

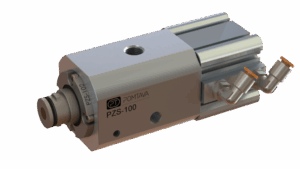

PZS-100

- Type of application

RTM Light / RTM Eco

- Flow range

0 - 3 l/min

- Temperature

up to 150°C

- Body

aluminum

- Headquarters

stainless steel

- Nozzle

hard synthetic material

- Pilot air pressure

max. 10 bar

- Injection pressure

up to 40 bar

- Assembly

with lugs and mold insert

RTM injection or vacuum head

PZS-200

- Type of application

RTM, injection or vacuum

- Flow range

0-5 l/min

- Temperature

up to 150°C

- Body

stainless steel

- Headquarters

stainless steel

- Nozzle

hard synthetic material

- Pilot air pressure

max. 10 bar

- Injection pressure

up to 100 bar

- Assembly

flanged, without insert (machined directly into the mold)

RTM high-flow injection head

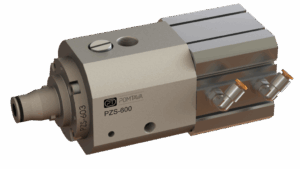

PZS-600

- Type of application

RTM, injection or vacuum

- Flow range

0-15 l/min

- Temperature

up to 150°C

- Body

stainless steel

- Headquarters

stainless steel

- Nozzle

hard synthetic material

- Pilot air pressure

max. 10 bar

- Injection pressure

up to 200 bar

- Assembly

flanged, without insert (machined directly into the mold)

Contact

Do you have any questions? Please fill in the form below to contact our sales department.

"*" indicates required fields