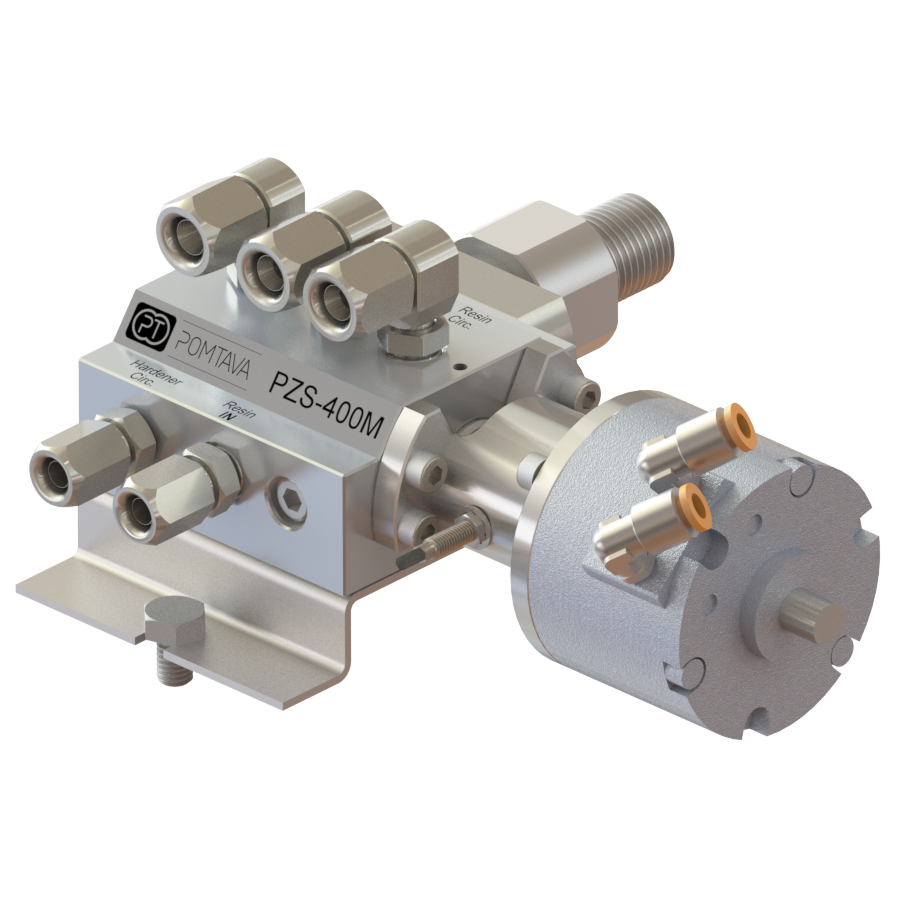

Mixing head

Mixing head – RTM injection technology

The PZS-300M and 400M mixing head, controlled by the injection machine, optimizes the mixing of epoxy or polyester resins for both small and large flow rates.

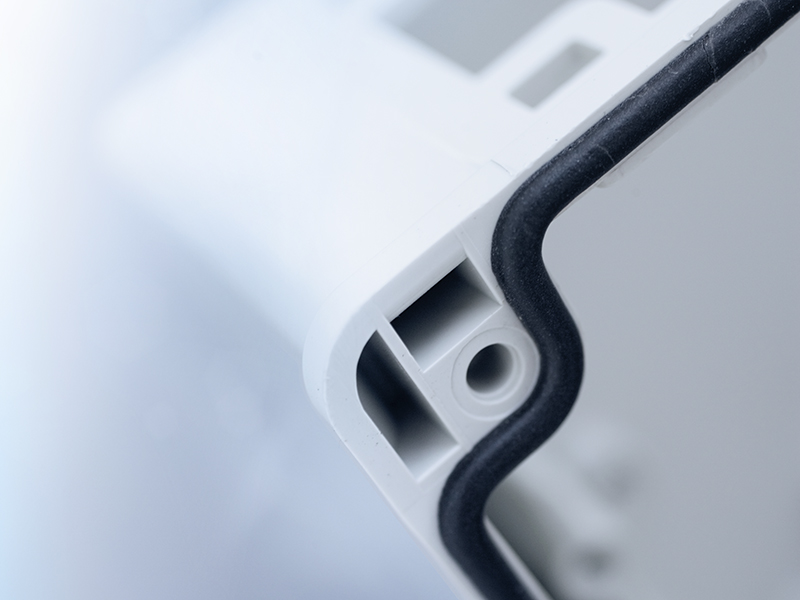

Thanks to its advanced design, it is equipped with a recirculation system that prevents deposits in the piping and maintains product pressure to ensure consistent and efficient injection. At the end of the cycle, the distributor shaft pivots to automatically activate recirculation and rinsing, simplifying maintenance.

Key strengths:

-

Homogeneous and reliable mixing of resins

-

Built-in recirculation function to prevent clogging

-

Automated rinsing for fast and effective cleaning

-

Suitable for small and large series production

-

Reduced downtime and optimized productivity

Applications:

Ideal for RTM processes in the aerospace, automotive, marine, renewable energy, and general industry sectors, the PZS-300M/400M mixing head guarantees consistent manufacturing quality and high durability.

Models

Mixing head

PZS-400

- Mixture flow range (l/min)

0.4 to 400 l/min

- Measurement accuracy

up to ±0.1 %

- Repeatability

±0.05 % (under the same conditions)

- Linearity

up to ±0.25 % of the current flow rate

- Material in contact with the product

AISI 303, AISI 316L, AISI 420

- Bearing

Tungsten carbide

- Possible injection pressure

up to 315 bar

- Pilot pressure

min. 2 bar max. 10 bar

- Working temperature

-40°C to +150°C

- Thread for position sensor

M5x0.5

- Output connection

G1/2"

- Channels

Base coat, hardener, rinse

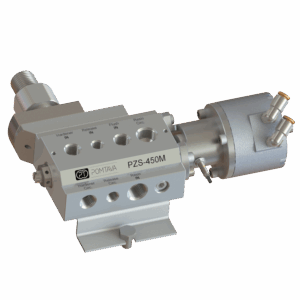

Mixing head

PZS-450

- Mixture flow range (l/min)

0.4 to 400 l/min

- Measurement accuracy

up to ±0.1 %

- Repeatability

±0.05 % (under the same conditions)

- Linearity

up to ±0.25 % of the current flow rate

- Material in contact with the product

AISI 303, AISI 316L, AISI 420

- Bearing

Stainless steel bearing

- Possible injection pressure

up to 315 bar

- Pilot pressure

min. 2 bar max. 10 bar

- Working temperature

-40°C to +180°C

- Thread for position sensor

M5x0.5

- Output connection

G1/2"

- Channels

Base coat, hardener, release agent, rinsing

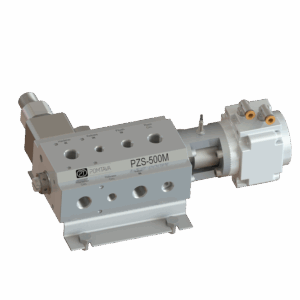

Mixing head

PZS-500

- Mixture flow range (l/min)

0.4 to 400 l/min

- Measurement accuracy

up to ±0.1 %

- Repeatability

±0.05 % (under the same conditions)

- Linearity

up to ±0.25 % of the current flow rate

- Material in contact with the product

AISI 303, AISI 316L, AISI 420

- Bearing

Tungsten carbide

- Possible injection pressure

up to 250 bar

- Pilot pressure

min. 2 bar max. 10 bar

- Working temperature

-20°C to +70°C

- Thread for position sensor

M5x0.5

- Output connection

G1/2"

- Channels

Base coat, hardener, release agent, rinsing

Contact

Do you have any questions? Please fill in the form below to contact our sales department.

"*" indicates required fields